小型铜米机

The mini copper wire granulator is a compact and efficient machine designed for recycling scrap copper wires. It integrates cutting, crushing, and separation functions to recover high-purity copper granules from waste cables. Despite its small size, this granulator delivers powerful performance, making it ideal for small-scale recycling operations, workshops, or home-based recycling setups. With advanced technology and user-friendly design, it offers a cost-effective solution for turning waste wires into valuable copper resources.

特点

-

High Separation Rate – Achieves up to 99.95% copper recovery, ensuring minimal material loss and maximum value extraction.

-

Integrated Dust Control – Equipped with a wind dust collection system to minimize dust and reduce maintenance frequency.

-

Compact & Portable – Designed with universal wheels for easy movement, perfect for flexible workspace arrangements.

-

User-Friendly Operation – Simple controls allow one-person operation, saving labor and increasing efficiency.

-

Versatile Application – Capable of processing various waste cables and wires, making it ideal for small recycling yards or home use.

Product Descripion

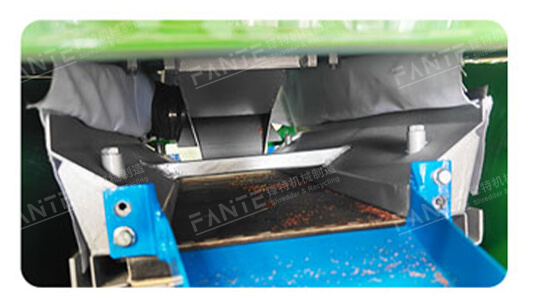

The vibration separator utilizes the difference in specific gravity between copper and plastic to achieve effective separation. Driven by an eccentric shaft, the separator generates controlled vibrations that allow the mixed particles to stratify by density. Assisted by a circulating fan, the copper and plastic particles are guided to different discharge ports, ensuring precise material classification and purity.

The mini copper wire granulator air blower generates a steady airflow that passes through the separation mesh, assisting in the sorting of copper and plastic particles. Under the influence of the eccentric shaft’s vibration, heavier copper particles settle and are discharged from the front outlet, while lighter plastic particles are carried upward by the airflow and exit through the rear outlet. This airflow-assisted separation ensures high sorting accuracy and material purity.

The mini copper wire granulator air bag and dust collector system efficiently captures dust generated from both the crusher and the separation bed. Equipped with front and rear dust removal fans, the system draws dust-laden air into the dust collection bags, effectively reducing airborne particles and maintaining a clean, environmentally friendly working area.

The electric control cabinet features a user-friendly control switch panel for easy and intuitive operation. The system includes overload protection to ensure safe and stable operation. All major electrical components come from reputable brands such as Schneider, offering high reliability, long-term durability, and compliance with industrial standards.

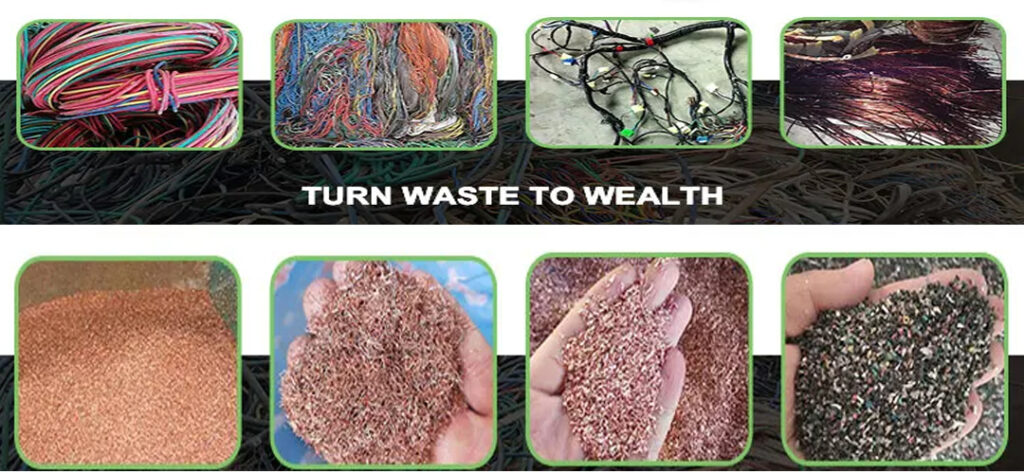

Mini Copper Wire Granulator Processing Effect

Product Prameters

| 模型 | FTG-02 | FTG-03 |

| 总功率 | 4.33kw | 5.33kw |

| 输出 | 30-50kg | 60-80kg |

| 适用范围 | 0.1-20mm | 0.1-20mm |

| 重量 | 450kg | 500kg |

| 尺寸 | 1150*600*1700mm | |

| Vibrating Size | 1050*300*550mm | |

产品实物图片